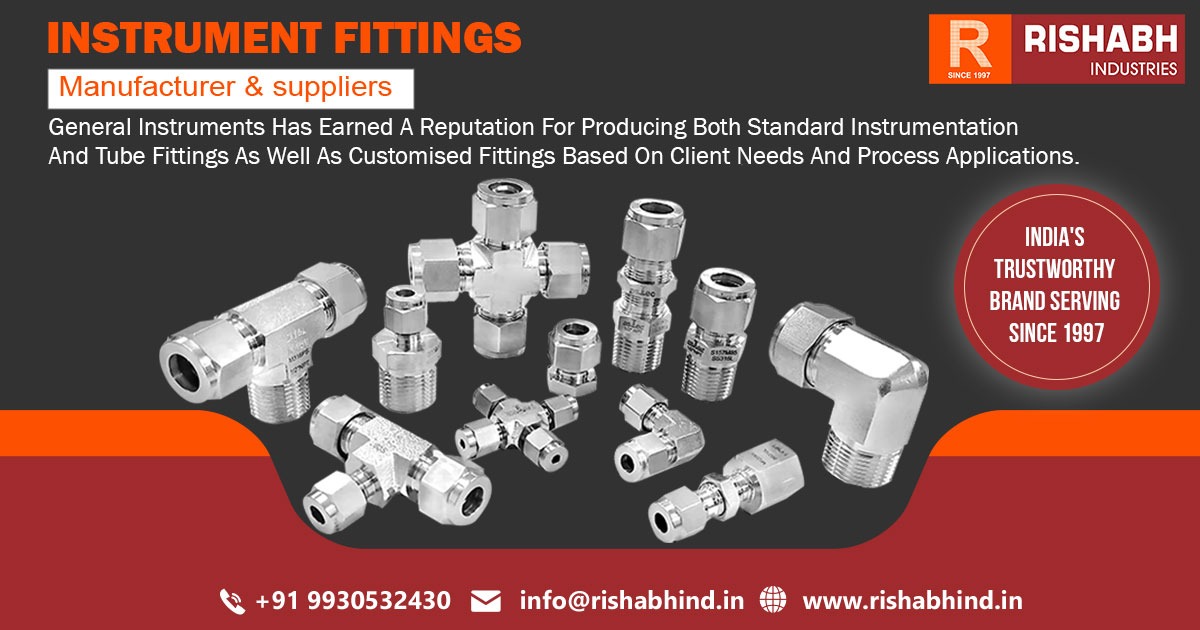

Supplier of Instrument Fitting in Andhra Pradesh.

Why Choose Rishabh Industries

- Rishabh Industries is an Indian-based industrial engineering company providing integrated solutions for manufacturing and process industries.

- Founded in 1997, the company has grown to become a leader in the engineering and manufacturing industry, offering cutting-edge solutions for a wide range of industrial requirements.

- With over 10,000 products in its portfolio, Rishabh Industries has established a global presence, serving customers in over 25 countries across the world.

- From custom-made machines and robotic solutions to third-party engineering services, Rishabh Industries has become a go-to partner for many industrial companies.

- The company’s mission is to bring efficiency, reliability and innovation through its solutions.

- Expertise and Experience

- Quality and Reliability

- Customization and Flexibility

- Cutting-edge Technology

- Customer Support and Service

- Competitive Pricing

Description of Product

- Instrument fitting refers to the process of installing and assembling instruments in various industrial settings to ensure their proper functioning and accurate measurements.

- It involves the careful selection, positioning, and connection of instruments such as pressure gauges, flow meters, temperature sensors, control valves, and other devices.

- The goal of instrument fitting is to create a reliable and efficient measurement and control system within industrial processes.

- Instrument Selection:

Choosing the appropriate instruments for the specific application is essential.

Factors to consider include the measurement range, accuracy requirements, environmental conditions, compatibility with the process fluid, and regulatory compliance. - Installation and Mounting:

Instruments need to be correctly installed and mounted to ensure stability, accessibility, and proper orientation for measurement and operation. Mounting options may include wall-mounting, panel-mounting, or direct mounting on pipelines or vessels. - Piping and Tubing Connections:

Instruments are connected to the process lines using piping or tubing.

Proper selection and installation of pipes, fittings, and connectors are vital to maintain flow rates, pressure integrity, and prevent leaks or contamination. - Instrument Calibration:

Calibration is a critical step in instrument fitting. It involves verifying and adjusting instrument readings against known standards to ensure accurate measurements.

Calibration may be performed during the installation process or as part of regular maintenance. - Electrical Connections:

In addition to mechanical connections, instruments often require electrical connections for power supply and signal transmission.

Proper wiring, grounding, and insulation techniques are necessary to ensure reliable electrical connections and minimize interference or signal loss.

Benefit of Product

- Accurate Measurements:

Proper instrument fitting ensures accurate and reliable measurements of various process parameters such as pressure, temperature, flow rate, level. - Enhanced Process Control:

Well-fitted instruments enable precise monitoring and control of industrial processes.

By providing accurate and timely data, instrument fitting facilitates better decision-making, allowing operators to adjust process variables and maintain optimal operating conditions. - Improved Safety:

Instrument fitting plays a vital role in ensuring the safety of personnel and equipment.

Properly installed instruments can monitor critical process parameters, detect abnormal conditions, and trigger alarms or shutdown systems in case of safety hazards. - Equipment Protection and Longevity:

In many industrial processes, instruments are used to protect equipment from operating outside safe limits.

By fitting instruments accurately, operators can monitor equipment parameters and take preventive actions, such as controlling pressure or temperature, to avoid equipment failures, breakdowns, or premature wear and tear. - Regulatory Compliance:

Various industries have strict regulatory requirements regarding process monitoring and control. Instrument fitting ensures that instruments meet these regulatory standards, enabling businesses to comply with legal and safety regulations. - Energy Efficiency:

Well-fitted instruments can contribute to energy efficiency initiatives by enabling precise control of energy-consuming processes. Accurate measurements and monitoring allow operators to identify and address energy wastage, optimize energy usage, and implement energy-saving measures.

- We Supply our product all over India.

- Rishabh Solution is Manufacturer & Supplier of Instrument Fitting . If you are interested then contact us. we will offer you our best quality product.