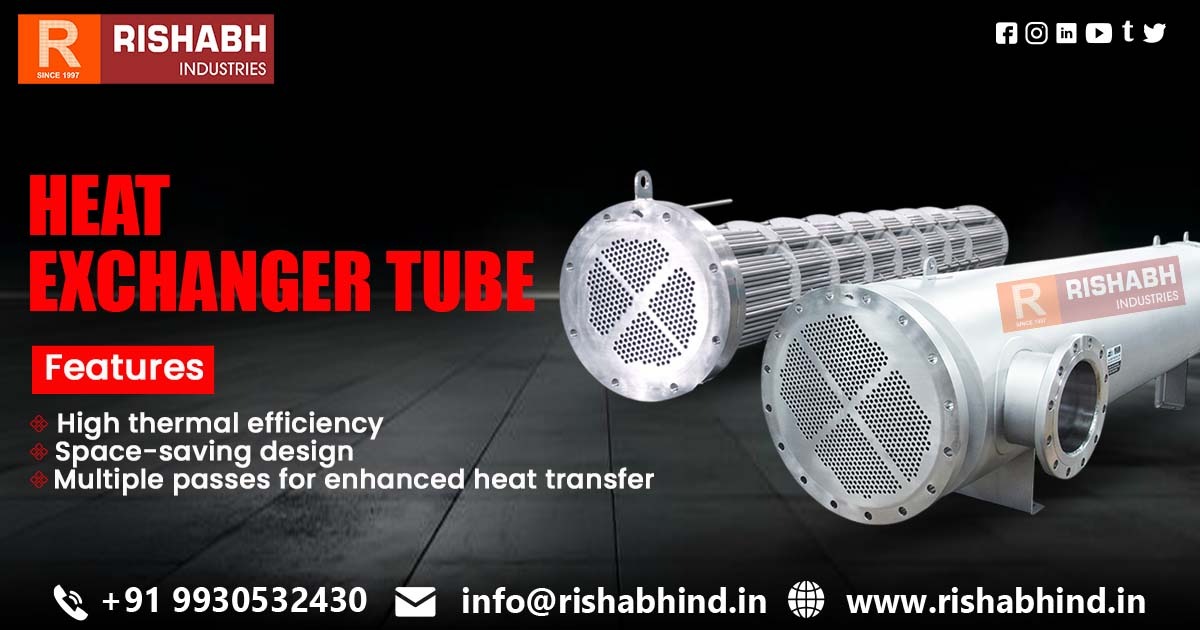

Rishabh Industries is a provide Heat Exchanger Tubes across India.

Our Manufacturing unit is located in Ahmedabad, Gujarat, India.

1. Introduction:

Heat exchanger tubes play a pivotal role in the efficient transfer of heat across various industrial processes.

Selecting the right tube can significantly impact the performance, longevity, and safety of your equipment.

We understand the critical role these components play and are committed to providing the highest quality heat exchanger tubes tailored to your industry’s needs.

This guide aims to help you make an informed decision when choosing heat exchanger tubes.

2. Understanding Heat Exchanger Tubes:

Heat exchanger tubes are the core components of heat exchangers that facilitate the transfer of heat between fluids. These tubes come in various types and materials depending on the application.

- Types: Seamless, welded, finned, U-tubes, straight tubes.

- Materials: Stainless steel, copper alloys, titanium, carbon steel, and nickel alloys.

Each type and material offers unique advantages suited for specific industrial requirements.

3. Key Factors to Consider When Choosing Heat Exchanger Tubes:

- Industry-Specific Requirements: Different industries have unique demands. For example, chemical industries require corrosion-resistant materials, while power plants focus on high-temperature tolerance.

- Temperature and Pressure Ratings: Tubes must withstand the operating temperature and pressure without deformation or failure.

- Corrosion Resistance: Materials must resist chemical attacks from fluids, especially in aggressive environments.

- Thermal Conductivity: High thermal conductivity ensures efficient heat transfer.

- Mechanical Strength and Durability: Tubes should maintain integrity under mechanical stress and prolonged use.

- Cost-Effectiveness: Balancing performance with budget constraints is essential for optimal ROI.

4. Industry-wise Heat Exchanger Tube Selection:

- Power Generation: Requires tubes that tolerate high temperatures and pressures, often using stainless steel or alloy tubes.

- Chemical Processing: Emphasizes corrosion resistance, favoring titanium and nickel alloys.

- Oil and Gas: Needs tubes with strong mechanical properties and corrosion resistance due to harsh environments.

- Food and Beverage: Prioritizes hygienic materials like stainless steel with FDA compliance.

- HVAC and Refrigeration: Commonly uses copper tubes for excellent thermal conductivity and ease of fabrication.

- Pharmaceuticals: Requires tubes with high corrosion resistance and cleanliness, often stainless steel.

5. Materials and Their Applications:

- Stainless Steel Tubes: Highly resistant to corrosion and heat, widely used across industries.

- Copper and Copper Alloys: Excellent thermal conductivity, ideal for HVAC and refrigeration.

- Titanium Tubes: Superior corrosion resistance, perfect for chemical and seawater applications.

- Carbon Steel Tubes: Cost-effective for less corrosive environments.

- Nickel Alloys: Withstand extreme environments, ideal for oil and gas sectors.

6. Rishabh Industries’ Advantage:

At Rishabh Industries, we combine quality, innovation, and expertise to deliver superior heat exchanger tubes.

- Quality Assurance: Adhering to international standards such as ASTM, ASME, and ISO.

- Customized Solutions: Tailored products based on your specific requirements.

- Technical Support: Expert consultation for choosing the right tubes.

- After-Sales Service: Dedicated support ensuring long-term satisfaction.

Rishabh Industries is a provide Heat Exchanger Tubes across India.

For inquiries, technical specifications, or to request a quote, contact our expert team today.